OR WAIT null SECS

- About Us

- Advertise

- Contact Us

- Editorial Info

- Editorial Advisory Board

- Do Not Sell My Personal Information

- Privacy Policy

- Terms and Conditions

© 2026 MJH Life Sciences™ , Pharmaceutical Technology - Pharma News and Development Insights. All rights reserved.

Approaching Elemental Impurity Analysis

Common approaches to analyze elemental impurities for compliance with regulatory requirements are robust but still have some limitations.

Elemental impurities present in a drug product are associated with potential safety and toxicological risks, and, therefore, appropriate analysis of elemental impurities is imperative to minimize patient exposure. “Elemental impurities are any elements that are not meant to be present in the final formulation of drug product,” asserts John Ferencz, manager, Trace Element and Contaminant Analysis at Avomeen. “These [impurities] can be introduced through numerous steps in the drug manufacturing process … Since most medications are taken on a daily or weekly basis, routine exposure to toxic elements and chronic health conditions could occur without proper impurities testing.”

Sources of impurities

According to regulatory guidance, there are two sources of elemental impurities, explains Paul Kippax, Pharmaceutical Sector director at Malvern Panalytical, which are either intentionally added impurities or non-intentionally added ones. For the former, impurities could enter the drug product via the use of catalysts in the synthesis of APIs, for example. Non-intentionally added impurities can include contaminants from naturally sourced materials or from manufacturing equipment, dose container systems, or water used in drug manufacturing or formulation.

“Several potentially toxic metals, such as palladium and rhodium, are used as catalysts or reagents in the synthesis of APIs and must be removed to limit patient exposure,” notes Daniel Ingles, technical leader for trace elements, Metrics. “Other metals, such as lead and cadmium, are not commonly encountered in pharmaceutical products but are controlled because they accumulate in patients over time.”

Taking cadmium as an example, which is known to be toxic, Ingles iterates the necessity of the analysis and removal of trace metals in pharmaceuticals. “Cadmium toxicity is associated with liver and kidney injury, osteoporosis, skeletal deformations, neurological deficits, and it’s classified as a category 1 carcinogen,” he says. “The biologic half-life of cadmium in the kidney is estimated to be between six to 38 years, and between four and 19 years in the liver (1). These half-lives reflect the fact that humans do not have effective elimination pathways for a number of toxic metals which have no known biologic function in humans. Excessive bioaccumulation is therefore regarded as potentially toxic and every effort must be made to analyse and limit patient exposure.”

“Raw materials used for chemical synthesis can contain traces of elemental impurities based on their production or origin source,” adds Johannes Hesper, product manager, Spectroscopy, Shimadzu Europe. “Catalysts and filters may release inorganic ions, and surfaces of tube reactors may react to a very low extent with the synthesis products. Additional risks are changes in ion strength and pH of synthesis media as often occurs during the process. Last but not least, formulation and packing can introduce impurities into the final pharmaceutical products.”

For biopharmaceuticals in particular, any materials that potentially come into contact with the final product should be inert, Hesper confirms. “Metal ions may interact with or covalently bond to the molecular structure [of the drug], replacing standard counter ions,” he says. “In the worst case, [the metals] are transferred into the human body where they can negatively influence the normal metabolism pathways.”

Regulatory requirements

In recent years, regulatory requirements for elemental impurity testing have been adapted and harmonized (2,3), and manufacturers are expected to demonstrate compliance via validated instrumental methods. “The most significant change in recent years is the withdrawal of the wet chemistry method for determination of heavy metals from all regulatory guidance,” states Ferencz. “Elemental impurities testing must now be performed using validated instrumental methods to ensure proper exposure limits are met.”

“For nearly a century, heavy metals were controlled using a benchtop wet chemistry procedure, of which the US Pharmacopeia (USP), European Pharmacopoeia (Ph. Eur.), British Pharmacopoeia (BP), and Japanese Pharmacopoeia (JP) had similar versions,” Ingles reveals. “The assumption was that any metals that formed an insoluble sulfide would respond to it. Unfortunately, in practice, it was not effective in detecting heavy metals at concentrations of interest to modern industry and was gradually phased out and replaced by more technologically advanced methodologies.”

Currently, drug manufacturers are required to demonstrate compliance with the International Council for Harmonization’s guidance—ICH Q3D (4)—and USP’s guidance—USP <232> (5), Kippax highlights. Additionally, USP <233> outlines which analytical procedures may be used for the detection of elemental impurities (6), he adds.

“ICH Q3D sets out the harmonized requirements for detection of 24 elemental impurities, depending on whether these are intentionally or unintentionally added to a product. These limits are based on an understanding of the bioavailability of each element,” Kippax says. “USP <232> sets the maximum permissible daily exposure (PDE) for elements, again based on an assessment of their bioavailability. In general, the guidance provided is harmonized with ICH Q3D, except for total parenteral nutrition (TPN) products.”

Hesper stresses that regulations around the detection of elemental impurities are updated frequently. “Thanks to modern detection technologies and methods, the limits of detection are getting lower and lower,” he notes. “New studies on the effects of such impurities trigger reconsiderations of risks and limits.”

“While the elemental impurities themselves are well defined, the exposure limits are under constant review by various governing and regulatory bodies,” concurs Ferencz. “There have been efforts to harmonize these limits internationally, but several regulatory agencies still choose to set their own levels based on alternative guidance.”

In terms of potential future updates, Ferencz reports that there have been several pushes to introduce separate limits for additional exposure pathways. “While drug introduction techniques have been expanding, the guidance has not, and parenteral now covers a large range of introduction techniques that do not necessarily have the same exposure risks for the various elemental impurities,” he says. “As more research is done on organ specific effects of different elements, the pressure for this [regulatory update] will increase.”

“Based on the actual push in terms of biopharmaceuticals, especially due to vaccine development, regulations on limits for metal contamination could again be under discussion to avoid influences on final products by metal ions,” adds Hesper. “As processes for release and approval of new pharmaceuticals and vaccines are getting shorter and faster, it becomes more important to reduce possible risks to a minimum.”

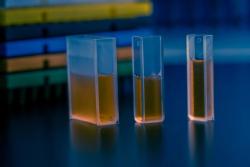

Commonly used techniques

The most commonly used techniques to analyze elemental impurities are inductively coupled plasma–mass spectrometry (ICP–MS) or inductively coupled plasma–optical emission spectroscopy (ICP–OES). “Both techniques use a high energy plasma to ionize any elements present in the sample preparation and detect them using elemental masses or elemental emission bands,” Ferencz states.

“The advantage of using ICP is that it can detect a wide range of elemental impurities at very low concentrations,” confirms Kippax. “This [capability] enables the product safety requirements for the main product types (oral solid dose, inhaled, and injectable products) to be assessed.”

Hesper concurs that ICP–MS is a robust and highly sensitive method used for trace analysis of heavy metals and adds that ICP–atomic emission spectroscopy (ICP-AES) has the ability to quickly analyze multiple elements in a large concentration range. “Of some use regarding elemental impurities is atomic absorption spectroscopy (AAS) for quantitative and qualitative analysis of many elements mostly in aqueous solutions and solids,” he says. “Rarely applied to the detection of elemental impurities is energy dispersive X-ray fluorescence spectroscopy (ED–XRF), which can analyze toxic elements in solid and liquid samples with high sensitivity.”

Some limitations

Even though ICP–MS is required to reach the desired levels of sensitivity, there are some limitations to the technique, according to Ingles. “The instrumentation is expensive and requires a trained analyst to operate it,” he says. “Additionally, there are technical complications in the analysis of arsenic and the digestion of nearly insoluble oxides of silicon and titanium.”

Although, it is possible to mitigate the complications with ICP–MS or ICP–OES through the use of appropriate sample preparation and background correction techniques, the cost and operation remains a barrier to businesses and leads to outsourcing, Ingles continues.

Another issue with ICP is that the sample preparation can be a lengthy process, asserts Kippax. “In addition, the preparation route, which involves sample digestion and dilution, requires a high degree of training,” he says. “As a result, although the method is routinely used in batch release, it is more difficult to apply during process development, where more rapid feedback and the application of quality-by-design (QbD) aids with process optimization and the development of a realistic process design space.”

There is also the possibility of gaining false positive results when using ICP–MS, as some elements have different isotopes with the same mass to charge relation, Hesper highlights. “But, basically, all 24 elements of the ICH classes can be analyzed using the ICP–MS technique,” he notes. “Gold, mercury, and osmium can sometimes be challenging. If the focus [of the analysis] is only on the seven most toxic elements, AAS can be the method of choice.”

A major limitation, as is the case with any instrumentation, can be sensitivity, stresses Ferencz. “Methods must balance matrix effects with detection limits to properly monitor for the elemental impurities at the required levels,” he says. “The other major limitation of these techniques is speciation. Because ICP requires the atomization and ionization of elements for analysis, it cannot provide the information about the valence states and molecular forms of the elements.”

Ferencz explains that even though speciation can be relatively more commonplace for certain elements, such as arsenic and mercury, for other elements it is still a niche technique. “As pharmaceutical companies experiment with the use of different elements, especially transition metals, in novel molecules and biologic therapies, there is a growing need to quickly and accurately assess whether the element exists free in the toxic elemental form or properly bound in the clinically proven novel product,” he asserts.

The next step

“In the future, species analysis may become more important,” reveals Hesper. For example, if an analyst was seeking to differentiate chromium III/VI rather than simply measuring total chromium, then liquid chromatography (LC) coupled with ICP–MS is more interesting, he states.

The use of chromatography was also key for the future for Ferencz, who believes that the next shift in elemental impurities analysis will be the use of high-performance liquid chromatography (HPLC) coupled with ICP–MS. “The ability to separate and speciate all elements in a drug product allows for a more thorough risk assessment, especially as studies continue to prove the marked difference in toxicity between free elements and various bound states,” he notes. “This technique is still only used for very specific novel drug products, but as the market grows, it will move to be the technique of choice.”

When considering the practical issues that are associated with ICP-based methods, Kippax asserts that XRF, which offers a faster turnaround of samples, cost efficiencies, and simpler measurement workflows, is starting to be more widely adopted. He explains that there are two main areas in which XRF provides the greatest advantages—in-process development and quality control (QC) screening.

“XRF is applied to guide process development scientists toward effective elemental scavenging processes, providing rapid feedback on the capabilities of the process,” Kippax says. “This [application] can speed the time to release of candidate batches. In this mode of use, ICP may be used as validation that a realistic endpoint is achieved, ensuring that the concentration of impurities within the final dosage will be within specification.”

In QC screening, XRF can be applied in the manufacturing process to track the elemental concentration, Kippax continues. “For some pharmaceutical products, this may be sufficient to meet ICH Q3D or USP <232> requirements, depending on the product dosing regimen,” he says. “Where XRF is unable to meet the requirements for detection, it can provide information on the general concentration of elements within a sample—this can then guide sample preparation for ICP, avoiding measurement failures caused by the elemental concentration within the sample being too low or too high.”

However, Ingles states that, despite the technique being useful in the detection of a variety of metals, there are significant cost and operation barriers to the implementation of XRF in the pharmaceutical industry. “Alternative techniques more commonly adopted in the agriculture and food sectors may at some point be considered for pharma, they include AAS, atomic emission fluorescence spectrometry (AES/AFS), neutron activation analysis (NAA), and anodic striping voltammetry (AVS),” he says. “As mentioned earlier, the techniques will need to meet ICH and USP reference requirements. There will also need to be a good use case to move away from the current, widely accepted approach.”

References

1. Agency for Toxic Substances & Disease Registry, “Cadmium Toxicity: What is the Biological Fate of Cadmium in the Body?” atsdr.cdc.gov [Accessed Jan. 11, 2021].

2. USP, “Elemental Impurities Updates,” usp.org [Accessed Jan. 11, 2021].

3. ICH, “The ICH Q3D(R1) Guideline Reaches Step 4 of the ICH Process,” Press Release, March 21, 2019.

4. ICH, Q3D (R1) Guideline for Elemental Impurities, Final Version (March 22, 2019).

5. USP, General Chapter <232>, “Elemental Impurities—Limits” USP 40–NF 35 (Rockville, MD, 2017).

6. USP, General Chapter <233>, “Elemental Impurities—Procedures” USP 38–NF 33 (Rockville, MD, 2015).

About the Author

Felicity Thomas is the European editor for Pharmaceutical Technology Group.

Article Details

Pharmaceutical Technology

Vol. 45, No. 2

February 2021

Pages: 46–48

Citation

When referring to this article, please cite it as F. Thomas, “Approaching Elemental Impurity Analysis,” Pharmaceutical Technology 45 (2) 2021.

Download Issue: Pharmaceutical Technology-02-02-2021

Download Issue: Pharmaceutical Technology-02-02-2021