OR WAIT null SECS

Dissecting Dissolution Testing

Advances in dissolution testing equipment are helping to meet user demands to a certain degree; however, more innovation in the space may be necessary for novel therapies, such as biologics.

Dissolution testing plays an important role within the bio/pharma sector, providing critical information for quality control and drug development. In an interview with Pharmaceutical Technology, Shailesh Vengurlekar, senior vice president, quality and regulatory affairs, LGM Pharma, provides more details on the role of dissolution testing, recent innovations in the space, and potential upcoming trends.

Key roles

PharmTech: What key roles does dissolution testing play, especially regarding quality control?

Vengurlekar: Dissolution testing assesses the absorption of a drug after oral consumption through the release of the drug substance from the drug product. The dissolution result of a product lot determines the ability of the lot to dissolve at the specified time (e.g., immediate, extended, or delayed) as intended.

During the formulation and development stage, dissolution data are utilized to assess different formulations and identify one that delivers the drug most effectively based on the dissolution criteria (as mentioned, immediate, extended, or delayed release). Consistent, reproducible dissolution data of a drug product can provide a level of assurance about its quality. Dissolution testing is also utilized to perform any equivalency study during changes or development of new formulations, ensuring continuous demonstration of product quality. FDA expects that new drug applications (NDAs) submitted to the agency contain bioavailability data and in-vitro dissolution data, which, together with chemistry, manufacturing, and controls (CMC) data, characterize the quality and performance of the drug product. Acceptable bioequivalence data, and comparable in-vitro dissolution and CMC data, are all required for approval of abbreviated new drug applications.

Current breakthroughs and rising needs

PharmTech: What are some recent innovations in dissolution testing? Can you describe their impact?

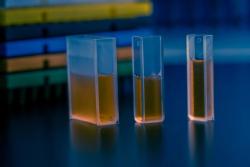

Vengurlekar: To my experience, dissolution equipment is more advanced and continues to evolve to meet user demands—for example, the equipment's ability to autosample, including multiple timepoints. Dissolution media have evolved over the years to mimic physiological conditions; media such as water, acid solution, simulated intestinal fluid, and simulated gastric fluid, including enzyme additions, have been developed and implemented. These tests help predict and simulate the in-vivo movement of the drug product through the gastrointestinal (GI) tract.

PharmTech: What are some chief concerns in dissolution testing?

Vengurlekar: Dissolution testing has to be accurate and reliable each and every time it is performed, regardless of when, where, or by whom. Thus, the method should be validated to demonstrate accuracy and precision. Dissolution method validation should be performed similarly to potency and purity method validation, which includes but is not limited to specificity and selectivity, accuracy, precision, linearity, range, and solution stability and robustness (including apparatus functionality: speed, temperature, and media type or volume). Acceptance criteria must be defined prior to performing the validation. Additionally, method validation must be performed in accordance with regulatory guidelines, such as USP [United States Pharmacopeia] and ICH [International Council for Harmonisation].

Looking to the future

PharmTech: How do the trends of the industry affect dissolution testing? Are there any upcoming trends that professionals should be on the lookout for?

Vengurlekar: The industry is coming out with more innovative drugs, such as biologics and cell and gene therapy, which are not the traditional oral solid dose, and the current standard dissolution techniques are not suitable for these innovative drugs. New innovative drugs will require the development of innovative and new dissolution approaches and analytical techniques. Some considerations affecting the development of such new techniques are the formulation (e.g., tablet, capsule, or powder), particle size, solubility, hardness, and stability of the drug substance.

PharmTech: What do you see in the future for dissolution testing? Is there one change in particular that could have an impact on analytical testing?

Vengurlekar: Dissolution testing is an important quality control parameter to assess absorption of a drug, as described above, and thus will continue to be important in the analytical space. However, changes to dissolution techniques, method, and instrument may be necessary for new and innovative drugs developed in the future.